Waterproof cycling Backpacks

Padded laptop pouches and accessory pockets are available for all of our backpacks.

Accessories

Velo Transit backpacks and pannier can be customized to fit Your individual needs.

Waterproof Backpack Liners

Welded rather than sewn seams are the only way to make 100% waterproofWaterski Test from velotransit on Vimeo.

Waterproof Cycling Backpacks

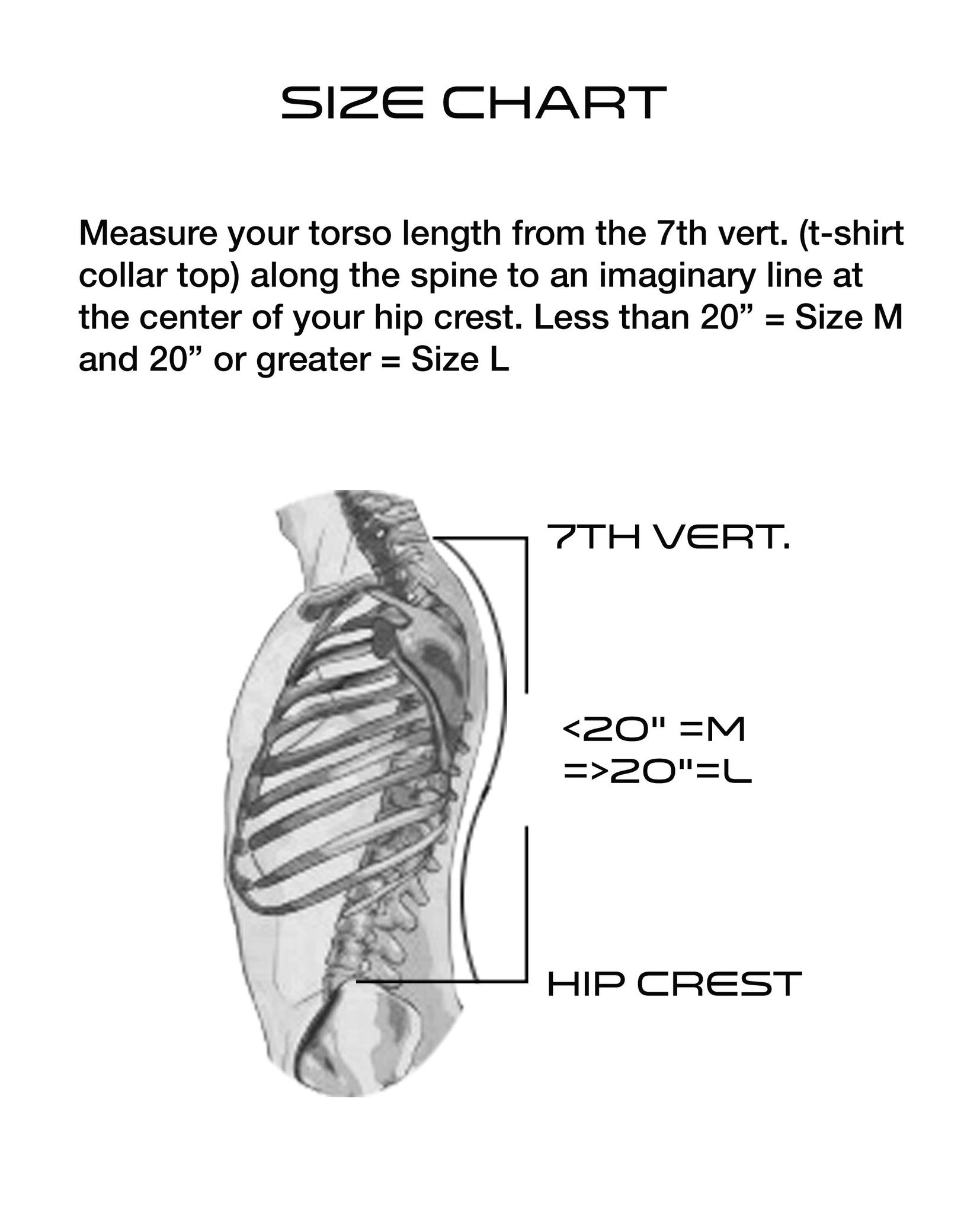

After you decide to use a cycling backpack for your bike commute rather than a bike pannier, you need to consider the following; 1.Is it waterproof? 2. Will it hold my laptop securely? 3. What volume should it be? 4. Is it comfortable to carry and will it fit me? 5. Can I customize it with accessories to fit my needs? 6. Does it clear my helmet when I ride and can I see behind me when I turn my head? 7. Will I be visible in traffic? Fortunately, Velotransit has incorporated all of these considerations into building our backpacks. 100% waterproof welded liners are built into every pack and pannier. Accessory laptop pouches and multiple side pockets let you customize your pack to your needs. Highly ergonomic, sized and gender specific harnesses give you unparalleled comfort and fit because one size fits no-one. Our lids and roll tops are specially designed to keep clear of you line of sight and multiple strobe attachment points and available bright colors help you stand out in traffic. All of this as well as durable fabrics and bombproof construction go into each and every backpack and pannier we make. Built right here in our own factory, we are proud to sew in the Made In Seattle label.

Design

We at Velotransit design our waterproof backpacks and panniers with direct feedback from our customers . We read every email from fellow commuters and take every suggestion on the phone seriously. Once we compile and analyze this feedback we make sure all of the needs of our customers are addressed in designing the new backpacks and upgrading our existing packs and panniers. We use Autocad to ensure an exact fit. Multiple prototypes are then made and Urban tested until we are happy with every detail of our Made in Seattle gear.

Cutting

Once a backpack is finalized, a marker is created and multiple layers of fabric are cut with a stack cutter. These cut pieces are bundled with webbing and buckles, delivered to home sewers and sewn into the individual parts.

Sewing

The parts from the home sewers are picked up and go through a QC procedure at our Seattle workshop ensuring that each piece meets our strict standards. Our In-House sewers take these parts and sew them into complete backpacks for each order, proudly attach the Made in America label and individually initial the serial # which is registered in our Lifetime warranty system.

Assembly

Lastly we insert the EV 50 foam back pad and HDPE frame sheet, attach the waist belt, perform the final Quality control and put the final initials on the serial #. Small controlled production runs like this guarantee you get the highest quality pack to protect your laptop and gear.

Testimonials

I've had my Edge 40 pack for two years and it works as well now as it did the first day I used it. I use it daily on my commute to work while biking, as well as utilizing it while hiking and traveling. Great all-around pack that comes in handy when the weather gets nasty. I've used the rain shield multiple times and have never had any water make its way into the pockets. The multiple pockets allow for easy storage and compartmentalization depending on need, and the laptop holder is great to protect my computer when biking.